Stairs

Stairs DIY Deck PlansStairs: How to Install Box Steps on Your Deck

Stairs: How to Install Box Steps on Your Deck DIY Deck PlansAnatomy of a Step

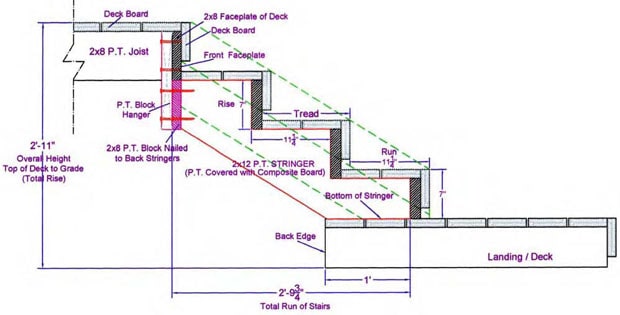

Steps are made up of three main parts. The top of a step is known as the “tread”. The “riser”, also sometimes known as the “toe kick” is the front face of a stair that runs from the top of the stair below, to the bottom of the tread. Many deck stairs have no risers, having open space under the tread instead. A “stringer” is the diagonal support running along each side of stairs in traditional stair construction.

Deck Steps

Stairs on decks are typically wide and short. This is for safety and ease of construction. A typical deck stair “tread” or top, is made with two deck boards, side by side. When building steps, it is essential to build every step the same height as the others to prevent tripping. A standard stair is 10 by 8, or approximately ten inches wide and eight inches tall.

For decks that are less than 18 inches tall, one step is typically sufficient. The simplest way to construct a single step is the box step. If your deck needs multiple stairs, multiple box steps, or stringer stairs are the solution.

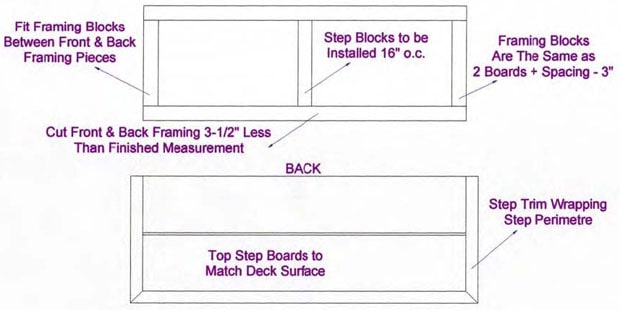

Single Box Step

Box Step Construction

- Cut five pieces of framing, three pieces 3 inches shorter than the width of your stair tread.

- Cut two pieces as wide as your stair tread from 2x8 PT material.

- Stand the front and back pieces on edge and position the three shorter pieces between them, perpendicular to the front and rear pieces to create a rectangle.

- Position one short piece flush with either end of the front and rear pieces.

- Position the remaining piece in the center of the rectangle.

- Fasten the box together using 3 inch deck screws.

Pro Tip

- Make your steps two boards wide.

- Keep your stair rises to a maximum of 8”.

- Do not install trim along the back edge of the step, it will create a trip hazard.

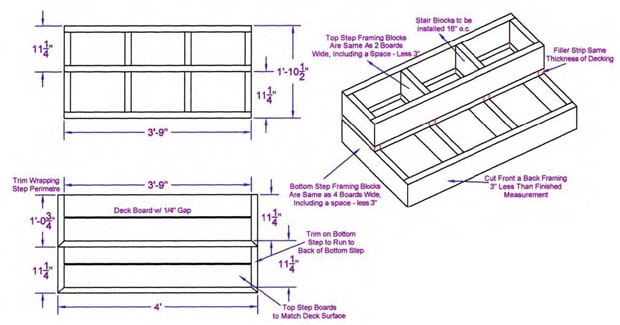

Double Box Step

Double box steps are built using the same techniques as for a single step. You will need one box for each step.

- Build your bottom step twice as wide as a single step.

- Build your top step as you would for a single step.

- Fasten the two frames together, with the back framing members flush with each other.

- Add decking on top of your frame.

Stairs: How to Install Wood Riser Stairs on Your Deck

Stairs: How to Install Wood Riser Stairs on Your Deck DIY Deck PlansWood Riser Stairs

Calculating Stair Rise

Use a string and string level to determine the height of the stairs.

- Mark the end of our stairs with a stake driven in at the point where the bottom riser will sit. The distance should be evenly divisible by twice the width of your decking boards. If not, adjust the position of the stake.

- Stretch your string out to the stake and adjust it until the level bubble is centered.

- Measure from the string to ground level at the base of the stake.

- Divide the height of the string by 8. Divide any remainder and add it equally to each step (for example, 33” deck height, equals 4 stairs, 8 ¼” each)

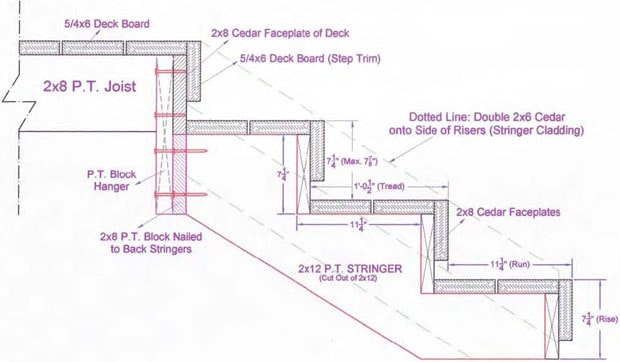

Stringer Stair Construction

Stair stringers are cut from 2x12 lumber. For exposed side stringers, use cedar lumber. Make one stringer for each 16 inches of stair width. Allow for light boxes if riser lights will be installed. Stair risers are cut from 2x8 material. Stair treads are made from deck board material.

- Use a framing square to mark stringers. Use the outside of the “L” to mark for rise and tread.

- Starting from the outside corner of the square, find the mark that indicates the dimension of your tread. Position the square with that mark on one long edge of the 2x12 and the corner of the square on the board.

- Starting from the same point, locate the mark that matches the dimension of your rise on the other “leg” of the square. Position it on the same edge you used for the tread mark.

- Trace along the square’s outside corner to mark a “v” notch with one angle of the V being equal to the tread, and the other equal to the rise.

- Repeat for each step, so that the tread starts where the rise below ended.

- Cut along the marks to remove the “v” sections.

- Cut the ends of your stringer at 90 degrees to the top tread, and the bottom rise, sot that the bottom will set flat on the ground and the stop will rest flat against the drop block.

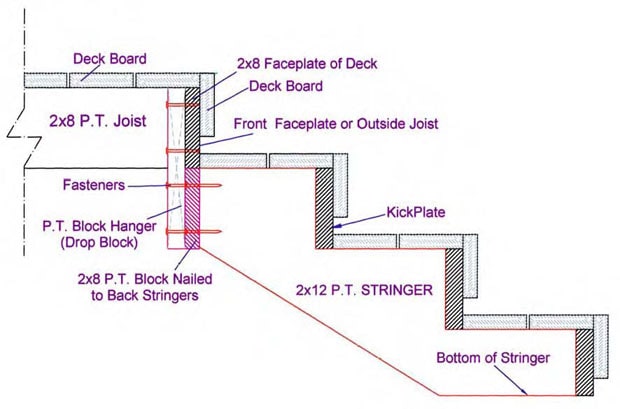

Attaching Stringers to Deck With Drop Blocks

Stringers must be securely attached to the deck at the top end. The bottom end is typically left free floating, with gravity holding it in place. Work carefully to ensure the stringer height is spaced properly down from the top of the deck and level.

- Attach 2x4 drop blocks at each corner and at least one in the center of your stairs.

- Position them so that the top end rests against the bottom of the deck boards, with one flat face against the inside of the rim joist, or deck face plate.

- Screw them in place.

- Attach a piece of 2x6 horizontally along the bottom edge of the rim joist across the width of the stairs.

- Screw through this stair “ledger” to the drop blocks.

- Fit the Stringers so that the back angle of the top fits flush against the face of the stair stringer you installed. Screw through the ledger into the stringer.

- Attach treads to the top of each step notch on the stringer with screws.

Attach risers to the front of each notch.

Drop blocks for stair support are fastened to the back of the front faceplate or outside joist. The stairs are secured to the drop blocks thru the back frame of the stairs.

DO NOT install drop blocks where rail posts or step lights are to be installed.

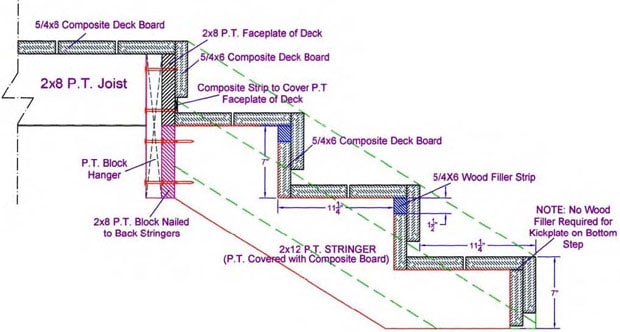

Low Maintenance Riser Stairs

To create composite deck stairs, use the same construction techniques described for standard stairs. Replace the treads and risers with composite material. Be sure that stringers are spaced no more than 16 inches apart. Composite material will not support the same weight as PT and other wood lumber. Add blocking as needed below stair treads to prevent sagging.

- Low maintenance stairs are built similar to wood stairs

- A kick plate of decking or trim is used rather than 1 ½ “ Cedar

- A wood filler the same thickness as the maintenance free kick plate supports the front edge of the tread and is covered up by the stair trim

- Stringer cladding may be one or two pieces wide depending on the width of the material

Riser Stairs and Landings

Landings are used to break up the run of the stairs and often to change the stair direction. Landings are supported by their own post, beam, joist structure.

Be sure to off set the center stair stringer if lights are being installed into the risers of the steps. Stair rail is installed at 32” to 36” in height on the stairs.

A 2x8 cedar trim board is fastened to both outside stringers just above each piece of riser trim. This adds strength to the stringers, boxes in the stairs, and closes in the space under the bottom rail to meet building code. Low maintenance decking and cladding can also be used for almost maintenance free stairs.

This landing has been used to change direction of the stairs. 42” hand rail was required on the landing for this high deck.

Riser Stairs that Finish on a Landing

To calculate number of stairs and stair rise and run:

- Overall rise (35”) divided by maximum rise (8”) = 4.375 = 5 stairs

- Overall rise (35”) divided by 5 stairs = 7” step rise

- Landing is 3 treads/ 4 risers (4x7”) below deck level

- Run is always 2 boards wide on stringer stairs

- Run (11 ¼ ) x 3 stairs = 33 ¾ “ Front faceplate to kick plate of last step

- We recommend that the landing extends 12” under the bottom step

- Total run (33 ¾ “) – 12” support of landing under step = 21 ¾ “

- Front faceplate of deck to back edge of landing = 21 ¾ “

Remember:

Deduct 1 ½” or thickness of the kick plate off of the top of the back of the stringer which allows for the front kick plate. Deduct the thickness of the decking off of the bottom of the stringer.

Stair Trim

Make sure that any riser trim that is added to your steps is positioned flush with the tread to prevent tripping hazards. Use trim at least 3 ½ inches wide and make sure it is completely secure. Smaller trim is likely to work its way loose and cause a hazard. Avoid trim on the sides or rear of treads. The goal should be to keep the surface open and free from possible obstructions.

Stairs: How to Install Wrap-Around Stringer Stairs on Your Deck

Stairs: How to Install Wrap-Around Stringer Stairs on Your Deck DIY Deck PlansRiser/Stringer Stairs with Outside Corners

The framing for stringer stairs with outside corners is similar in every way to standard stringer stairs, except at the corner. Space stringer every 16” OC and mount them using drop blocks as described in the stair building section. When calculating corner miters, take the angle of the corner, for example a 45° corner is made up of two 22 ½ ° miters. The risers, or toe kicks, get mitered at the corners where the meet the riser coming from the opposite angle of the corner.

- Mark, cut and install all stringers, checking for level.

- Install an additional stringer at the inside of the corner, on each angle of the corner to provide support for the corner of the stair.

- Measure and cut each riser, or toe kick, to fit each stair. Cut the mitered end first, then measure and cut the square end for accurate, simple miters.

- Attach each riser, fastening them to the stringers with at least two deck screws, or nails, wherever they riser meets the stringers.

- Measure and cut any notches, or other adjustments required. *In the photo, the riser on the second stair down is notched for a step light and wiring.

- Add wiring and other internal structure while the stairs are still open and accessible.

- Add stair treads once all framing and internal construction is complete.

- Install decking boards on top of treads, if needed.

- Install trim once all other parts are in place for best appearance.

Another option for framing outside corner supports is to add solid lumber blocking in the space between the two stingers closest to the corner.

- Measure the corner space and mark it out on a piece of 2x12 PT lumber.

- Cut along the lines with a circular saw, or miter saw.

- Dry fit the blocking and make any adjustments needed for a perfect fit.

- Set the blocking so that the top edges are flush, or a little below the top edge of the stringers and riser. This makes tread installation simpler.

- Nail or screw through the stringers and riser into the edge of the blocking on all sides to fasten it in place.

- Use multiple pieces, if needed, to cover the entire space. Install pieces from the rear out for easier installation.

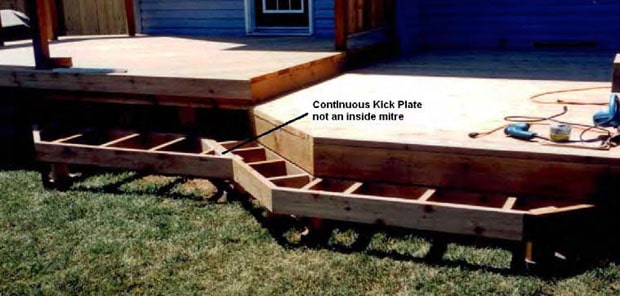

Box Steps with Inside Corners

When building box steps with inside corners, frame one side of the corner as if it were stand alone. The toe kick goes from the face plate back to the drop block. Add blocking and Fasteners as if this stair were complete. Add the opposite angle so that it butts up to this toe kick. This a much stronger joint than if the toe kicks were mitered together.

Overlap outside corners, with the front piece mitered to fit the angle of the opposite face. Miter the back piece to sit flush against the back of the front toe kick at the joint.

Always build the bottom step of a box step first to provide a foundation for the steps above. For box steps that end with an angle, install the toe kick so that it runs parallel to the faceplate of the deck. Measure the angle off of the toe kick. *In the photo, the end of the step runs 45° back from the toe kick. Overlap these corner joints, rather than joining them on the miter for a stronger joint. Since the outside end piece has the least support, extend it over the toe kick, flush with the face of the toe kick for added strength.

Measure using the bottom step as a template for your top step. Layout the top step so that the backset is even on all faces, unless the ends are to be longer or shorter. If your box steps are large you will need footings. Space them as you would for deck support and install the footings and posts before you begin frame construction for simplicity.